Technology

Photo: Aree Sarak / iStock / Getty Images Plus

Aim High

with AI

Tools for Chemical Safety and Workplace Compliance

By Alan L. Johnson

A

chieving product compliance and ensuring workplace safety are increasingly complex endeavors. Safety and compliance personnel play a pivotal role in safeguarding workers from chemical hazards, face mounting challenges to meet global regulations, track chemicals of concern, and adapt to evolving reporting requirements and deadlines.

As an example, on May 7, 2024, the Occupational Safety and Health Administration (OSHA) adopted The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) Revision 7, which entered into force on July 19, 2024. The deadline for compliance with all modified provisions is January 19, 2026. OSHA estimates that the GHS v7 update will impact up to 94% of SDS and 64% of shipping labels.1 And this revised HazCom standard is just one of dozens of global regulations pushing companies to provide thorough reporting, accurate labeling, universal access, and greater transparency in order to keep stakeholders across the value chain safe. However, the complexity of products today makes manually tracking chemicals used in products an impossible task.

Fortunately, advanced AI technology offers companies a powerful tool for upping their compliance and workplace safety game in ways never before possible. With the adoption of the appropriate AI compliance tools, safety and compliance teams can meet the rigorous demands of the increasingly complex compliance landscape.

Chart: 3E

Obstacles to Workplace Safety Compliance

Navigating global chemical regulations and ensuring workplace safety compliance are significant challenges for safety teams.

Keeping track of regulations: Regulations are evolving quickly and differ from region to region, country to country, and state to state. Navigating a growing number of regulations, distinguishing where their rules apply, and producing accurate reports and labels to spec can be exhausting for even the most seasoned teams.

Maintaining accurate SDS and training: SDS are not simply created for compliance purposes. Their primary purpose is to convey complete and correct information about hazardous materials and outline safe handling, storage, and emergency response procedures in case of a spill. Not only must the correct, updated and compliant SDS be made available, but personnel must understand how to read them.

Making the right information accessible to the right people: When it comes to workplace safety, having the right information about which chemicals of concern are used in which products and processes, where they are stored, and exposure response plans is critical to minimizing harm. Hard copy binders full of SDS can be difficult to update with the latest safety data sheets, particularly in a company with multiple locations. They can also be difficult to locate in an emergency and may or may not contain SDS in the native languages of on-site personnel.

Fostering a culture of safety: Creating a proactive approach to safety means providing tools to maintain up-to-date information, access it when and where it’s needed, and understand what’s next in terms of regulations. A safety-first culture requires the right tools, leadership support, and monitoring/drills to evaluate preparedness.

How AI Compliance Tools Transform Chemical Safety

AI has the potential to help safety teams advance their chemical compliance and workplace safety by optimizing data accuracy and exponentially enhancing the productivity of a limited workforce. AI compliance tools enable safety teams to streamline SDS management and meet global chemical regulations efficiently.

Enables scalability: AI can process data from more sources more quickly than is possible with humans and/or traditional automated systems. With the right data sources fueling AI, it is possible to produce meaningful summaries of global chemical regulations, information about substances of concern, and reporting requirements from multiple regulatory frameworks. Best of all, AI is unlimited in its ability to handle growing volumes of data to meet the dynamic demands of regulatory compliance in the chemical industry.

Normalizes data: When it comes to authoring, updating and standardizing SDS, AI can effectively validate and cleanse nonstandard data inputs. This technology can swiftly eliminate duplicates, standardize input formats, and discard non-uniform data with remarkable speed and consistency. Leveraging machine learning, AI can also recognize associations between variable verbiage that refers to the same concept, ensuring accurate classification of varied references. The use of AI allows safety and compliance professionals to focus on more critical tasks associated with ensuring higher standards of safety and regulatory compliance.

Promotes usage: AI’s intuitive interface promotes adoption. Natural language queries make highly technical data more accessible to expert and non-expert users alike. AI tools allow personnel to search for information on topics from substances of concern to safe handling instructions. AI can also accommodate multiple languages easily. AI tools engineered specifically for chemical compliance can empower non-technical stakeholders with insight and information to positively contribute to chemical workplace safety efforts.

Companies that plan to invest in AI should understand the value of purpose-built AI tools and carefully vet solutions to ensure optimal results.

Day-in-the-life: Taking the Pain out of Research

A real-world example highlights the value of AI in a daily usage scenario. Consider a chemical company that wants to send a 5 kg sample of a product to Germany. The formula includes a hazardous mixture, but it’s under industrial use. In most organizations today, this question would trigger the following manual workflow:

• Dig through ECHA compliance documentation or the Annex VIII guidance

• Review exemptions for industrial use and small volumes

• Cross-reference concentration thresholds or data completeness

• Email a consultant or legal advisor

• Wait for a response for hours or days

Using the power of AI in regulatory compliance software, the user could simply enter the query: “Do I need a Poison Centre Notification for xyz product to Germany?”

The AI output would specify:

“No PCN is required for this shipment under current ECHA rules. The mixture is classified as hazardous, but is for industrial use and does not exceed the notification thresholds for non-consumer products. See Annex VIII, Article 2.3(b) for the exemption. [Link]”

This kind of immediate clarity allows the team to move forward confidently, saving time, resources, and reducing risk.

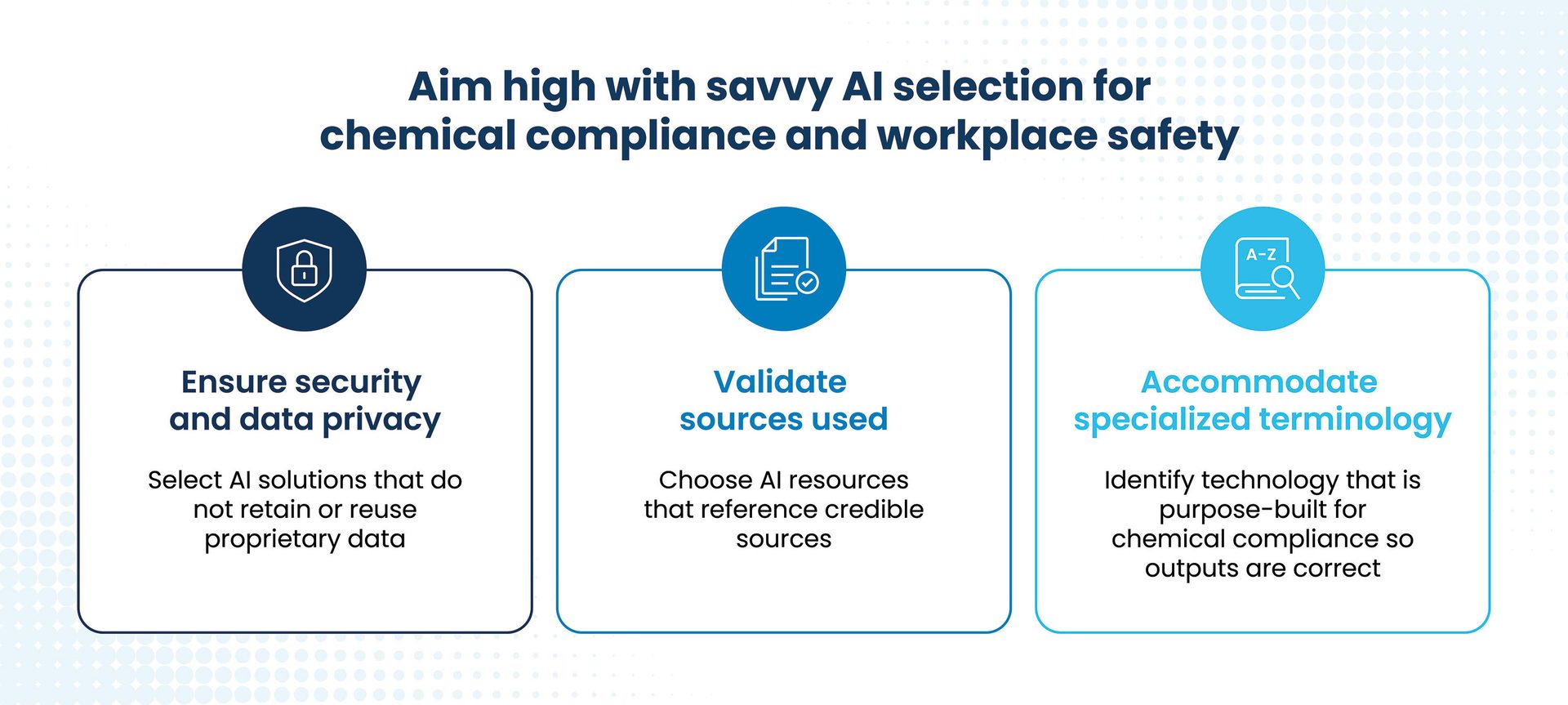

Next Steps for Companies to AIm High

The value of AI in safety and compliance is undeniable. However, not all AI tools are appropriate for these purposes. Companies that plan to invest in AI should understand the value of purpose-built AI tools and carefully vet solutions to ensure optimal results. Here are some considerations to keep in mind.

Security and Data Privacy in AI

Most large language models (LLMs) store and use prompts entered for the purposes of training the AI tool. This means that proprietary substance and formulation data could be captured and used in responses provided to other users or even competitors. Therefore, it’s essential to choose an AI tool that does not retain or use proprietary data. Companies should thoroughly assess AI solutions for their privacy and security policies to protect sensitive chemical formulation data.

Tapping the right data sources

Generalist AI tools may evaluate sources of information that are incomplete or, worse, incorrect. Use AI tools that are trained to reference credible sources. Another thing to remember is that general AI tools often have information cut-offs, meaning that latest information is not included in the evaluation. This is a problem when it comes to chemical compliance and workplace safety.

Specialized Terminology and Precision Outputs

Understanding language nuances is crucial in highly specialized fields such as regulatory compliance. AI tools purpose-built to support chemical compliance are trained using industry-specific terminology, and acronyms in different languages to ensure accurate evaluation and outputs. It's not just about translating reports into other languages, but also about accurately categorizing inputs in different languages from the outset.

Safety and compliance teams empowered with the right AI compliance tools have the potential to streamline regulatory compliance, optimize workplace safety and achieve greater supply chain visibility. Teams are only beginning to discover use cases for AI that can advance their efforts and productivity. As companies embark on their journey to navigate the complexities of an increasingly regulated landscape, AI can help them advance their capabilities alongside growing rigor of compliance demands.

Alan L. Johnson is the Managing Director, Chemical & Workplace Safety at 3E. Mr. Johnson has more than fifteen years of proven leadership in business development, strategic alliances, and product management. Prior to joining 3E, he held senior business development and product positions with market leading software companies including Turning Technologies, BlueTie Inc. and The NASVF.