Technology

Photos courtesy of Rite-Hite.

Smart

connections

Sensors and other equipment help improve safety and productivity in the plant

By Tim Kubly

ensors, smart-connected equipment, and software are changing the way we operate in our homes, cars, offices and even industrial facilities. Forward-thinking industrial equipment manufacturers have been developing ways to make their products smart and inter-connected in recent years. From the loading dock to the plant interior, equipment that can harness the power of data can help maintenance, safety and facility managers do their jobs better and make more effective long-term improvements. With the increased focus on productivity along with the always important need for safety, industrial facilities have a growing number of options at their disposal.

S

Sensors add safety

One option that offers an immediate positive impact to facility safety is integrating sensors into existing equipment. Solutions that were originally developed for one specific job – like a vehicle restraint to help secure a trailer or a loading dock leveler to bridge the gap from facility floor to trailer bed – can now be optimized with sensors that offer proactive warnings in potentially unsafe situations. From out on the drive approach to the busy loading dock, these sensors activate audible and visual warnings while also integrating with controls to provide a safer sequence of operations.

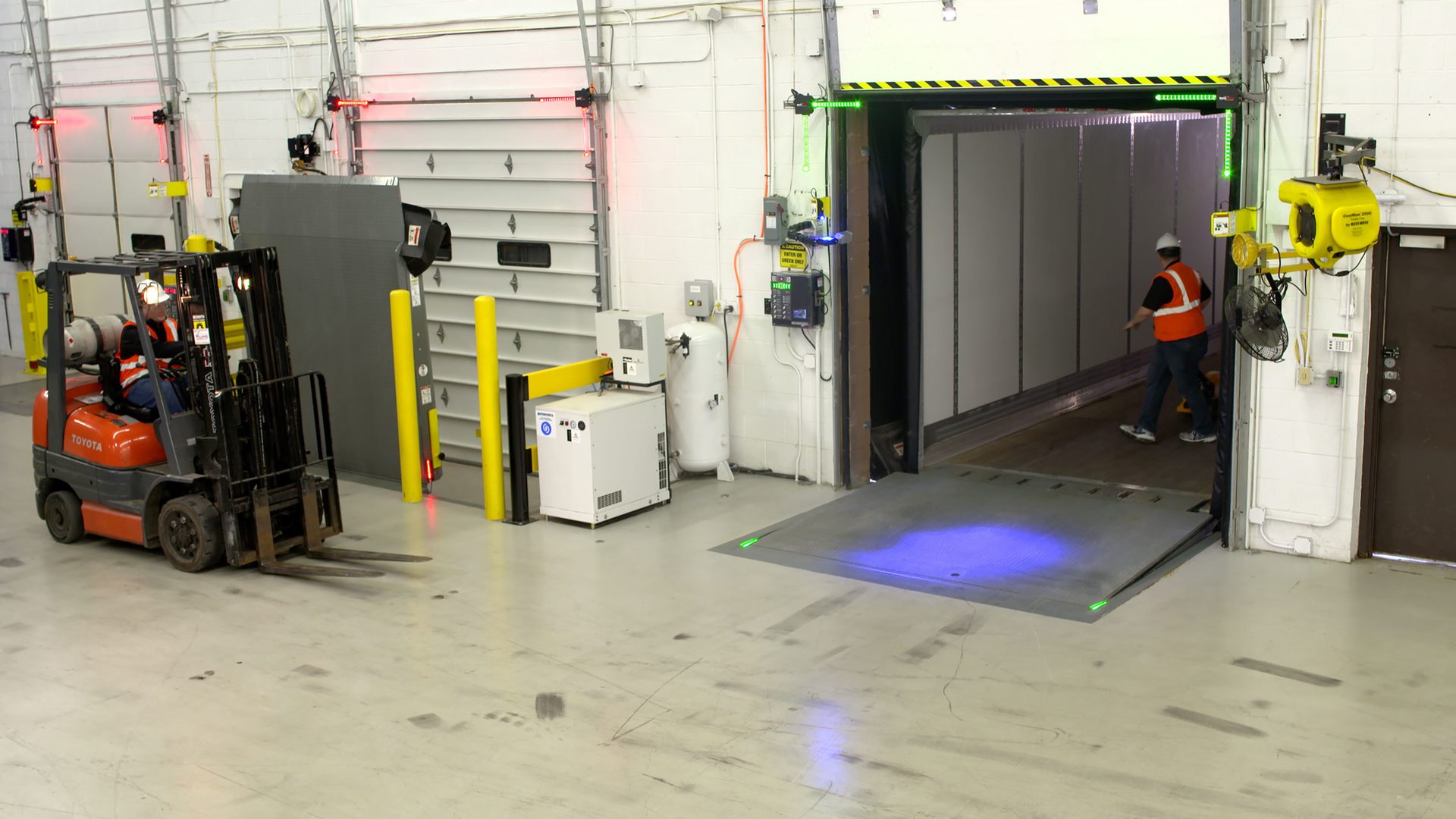

For example, industry-leading vehicle restraints can now incorporate sensors that actively detect motion on the drive approach. Activated by a trailer backing into that dock position, an audible and visual alarm that is either embedded in the restraint or mounted as a standalone unit notifies personnel to vacate that position. This sensor enhancement directly addresses the fact that semi-tractor trailers are the second leading cause of back over fatalities in the United States. Similarly, inside at the dock, motion-activated sensors help prevent pedestrian-forklift accidents which account for 80% of all reported forklift accidents. Enhancing a facility’s blue light policy, the system shines a blue light onto the leveler when activity is detected inside the trailer. In addition to extending a dock worker’s reaction time, the system can also be interlocked with vehicle restraint controls to prevent premature trailer disengagement while also audibly alerting an unsuspecting worker if they’ve entered an unsecure trailer. If a facility has a drive-thru application, sensors placed in the vertical-storing leveler’s pit, disable operation if motion is detected there, to help prevent personnel injury when servicing the equipment or cleaning the pit, among other things. The leveler cannot be operated until the pit is cleared and the dock worker engages the controls.

Most recently, visual management tools at the dock help facility’s increase productivity. Monitoring the total duration of loading activities, dock timers either count up or down and automatically begin when the vehicle restraint safely secures a trailer to the facility. When integrated with an optional trailer presence sensor, which helps confirm trailer presence without the need to step outside on the dangerous drive approach, the timer begins counting once a trailer is detected at the dock position. The dock timer stops counting when the vehicle restraint disengages the trailer, signifying the load is complete.

In the most forward-thinking operations, these safety features are incorporated into an advanced dock control system which integrates multiple pieces of equipment (including the vehicle restraint, leveler, dock barrier and dock door) programmed to work only in a safe sequence of operation. However, they can also be added to existing equipment as standalone products, regardless of restraint type or if the facility just chocks tires.

Loading dock equipment

Just as many cars and household appliances now collect data, interact with users, and alert people to potential problems (like an open garage door or an overdue oil change), industrial equipment is adding similar functionality. At the loading dock — a critical point of access for most companies — the need for insights into safety and efficiency is a growing trend.

Customers want their equipment to give them real-time alerts about problems they are trying to address so they can take more immediate action. Freezer and cooler doors are a good example. If a smart connected freezer door indicates the door was left opened or did not close properly (and is thus causing the product inside to melt or spoil) it will do more than just log that data for future use — it will also send an alert, so the problem can be fixed right away. Similarly, smart connected dock equipment can notify safety managers to a dock door left open without a trailer present – a clear fall hazard.

Software enters the industrial facility

In its most limited application, the data captured by a piece of equipment can help managers uncover problems at each individual location. Data is much more impactful when it is aggregated across a facility, which is where dock management software and dashboards come in. These tools help the shipping and receiving office personnel see what is happening at each dock, analyze usage of each dock, and even get safety alerts when a dangerous situation arises. They can also track which pieces of equipment are due for maintenance. Other recent logistics management innovations include systems that track when carriers arrive at a facility, manage those drivers in a queue, establish priorities, and facilitate direct communication between drivers and the shipping/receiving office.

The expectations of facility managers to run an efficient and safe operation are rising dramatically among both employees and company stakeholders. The addition of new employees into a facility is also driving up the need for improving operations. The implementation of dock management software and dashboards can help meet those expectations. When employees start using a software program to handle what were previously manual tasks, or when they can monitor multiple pieces of equipment through a dashboard, real value is gained. Data from smart-connected equipment can easily be collected and displayed in meaningful, real-time screens, reports customized and distributed, and so on. Over time, all decision makers will better understand how each piece of equipment is performing and more.

Dock management

With a tight labor market, ever-changing supply chain challenges and all kinds of economic issues, industrial managers and executives are looking for more effective ways to run an operation. Solving issues like driver wait times, miscommunication, and how to handle increased daily logistics volume are top-of-mind. Thanks to new software solutions, companies can streamline the conversation between shippers, carriers, and dock management staff. They can assign carriers to docks without the hassle of manual dock checks and without a driver ever leaving their cab. And what’s more, being able to view real-time dock or door utilization across the entire facility, allows for better decision making and can help reduce expenses.

Many of the people I talk to are interested in making their facilities or warehouses more effective. Once we’ve had a conversation about ways to use technology and data from our equipment, they start to get really excited about the possibilities. This is definitely a shift I see in the industry.

The next level

Facilities focused on improved safety and productivity at the loading dock and within the plant now have more options available to them. The time is now to learn how sensors, upgraded, or new smart connected equipment and software can help take a company to the next level. The benefits will range from identifying safety improvement opportunities to analyzing trends and utilization to safety alerts that can be acted on immediately. It is a critical and exciting time for material handling, logistics, and industrial companies wanting to be the best they can be.

Tim Kubly is Business Development Manager at Rite-Hite Digital Solutions.

Note: The information herein is provided as a general reference regarding the use of the applicable product(s) in specific applications. This information is provided without warranty. It is your responsibility to ensure that you are using all mentioned products properly in your specific application and in accordance with all laws and regulations.