Training

Photo: WUT789 / iStock / Getty Images Plus via Getty Images.

strengths

& weaknesses

Understand your

jobsite safety climate

Courtesy of CPWR.

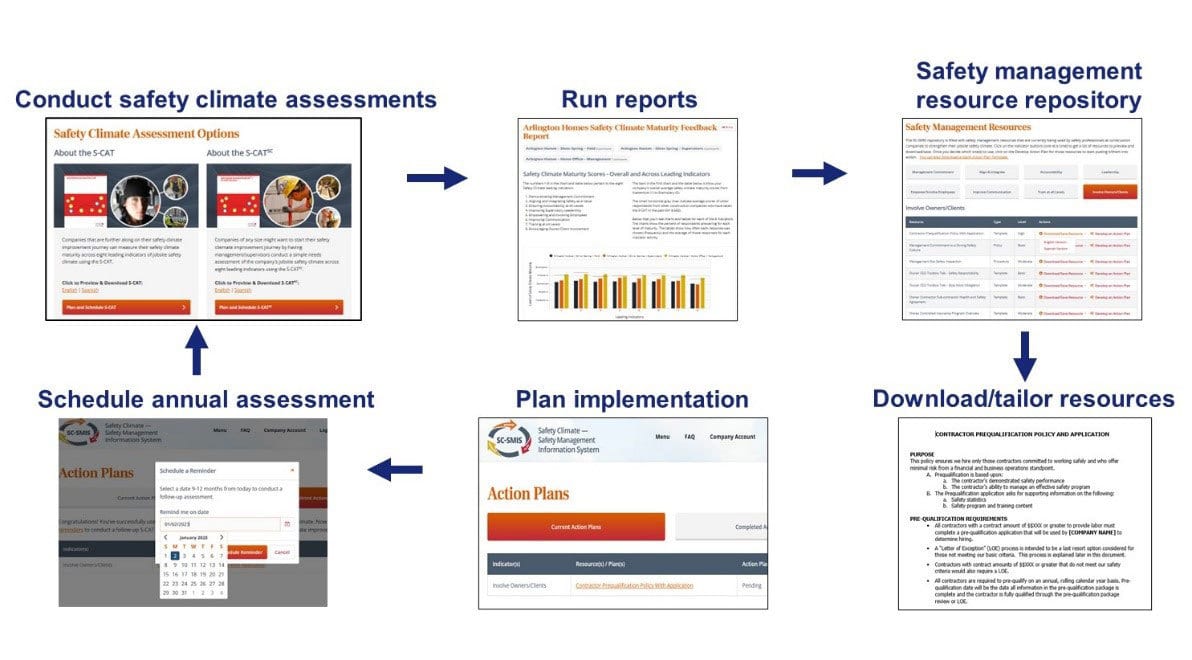

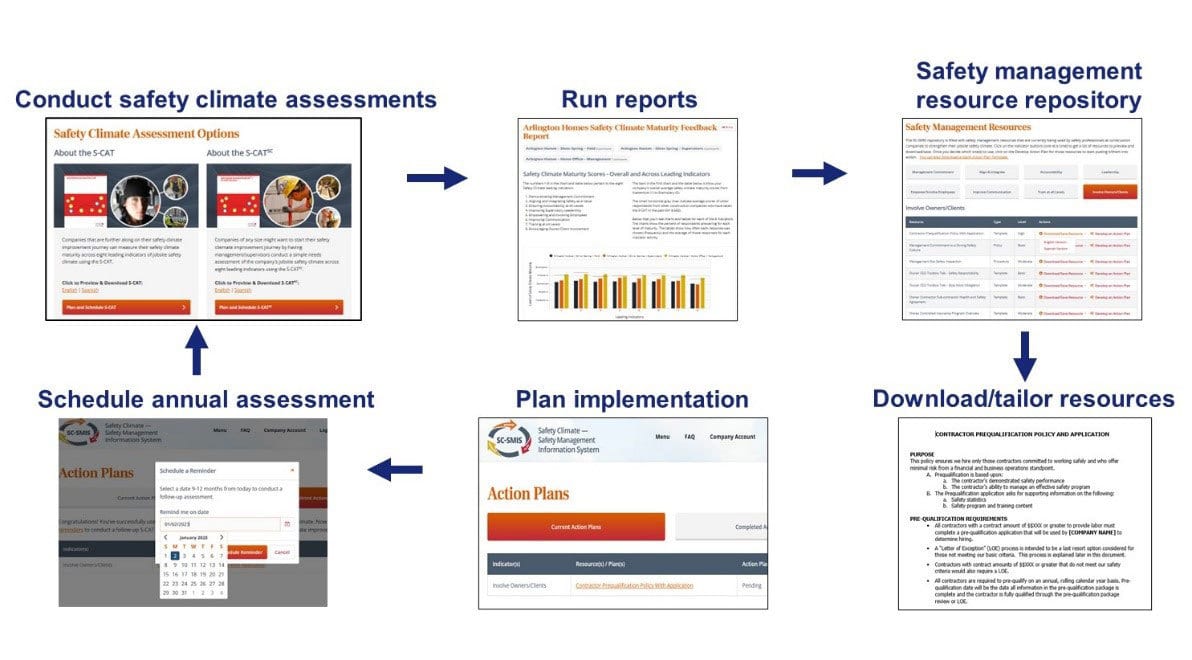

CPWR provides free online tools & resources for continuous improvement

By Dave Johnson

efugio Alvarez. Eric Buschard. Rebecca Klein. Aaron Boggs. Four safety and health professionals from across the country who share a common bond: all enthusiastically use a free safety climate assessment and improvement tool created by CPWR – The Center for Construction Research and Training (www.cpwr.net), a global leader in construction safety and health research, training and service. CPWR, a non-profit agency based in Silver Spring, MD, developed the Safety Climate-Safety Management Information System — SC-SMIS — (www.scsmis.org) under the direction of Dr. Linda Goldenhar, CPWR Director, Research and Evaluation and with input from more than 70 safety and health expert stakeholders. This innovative web-based program is accessible at no cost to any company, both inside and outside of construction, interested in jobsite safety climate and safety management improvement.

Construction is no different than many businesses where small firms can’t afford to have full-time safety and health leaders able to focus on strengthening the company’s jobsite safety climate.

R

Measuring maturity; assessing needs

Companies of any size or available resources can start their safety climate improvement journey by using one of the system’s two assessments developed by CPWR (with stakeholder input) to either measure their safety climate maturity or conduct a simple needs assessment of the company’s jobsite safety climate across eight leading indicators:

• Demonstrating Management Commitment

• Aligning and Integrating Safety as a Value

• Ensuring Accountability at All Levels

• Improving Supervisory Leadership

• Empowering and Involving Employees

• Improving Communication

• Training at All Levels

• Encouraging Owner/Client Involvement

“Climate is what the jobsite environment feels like every day to employees,” says Refugio Alvarez Jr., safety director of King of Texas Roofing Company. Critical to building trust and helping to ensure participation in the survey is that all assessments are anonymous. “Because it’s anonymous, it opens the door for guys to be honest without giving names or being identified,” says Alvarez. “When you ask employees for assessments at safety meetings, true feelings are not always expressed. You have guys who want to say the right thing to look good.”

Grading performance

Employees, supervisors, managers, really anyone in an organization asked to complete the Safety Climate Assessment Tool (S-CAT) grade the company’s performance on a number of activities for each indicator. For example, the indicator – Demonstrating Management Commitment – lists six activities to be assessed. One of them is: Is management present and visible on the jobsite? Answers range from inattentive – management rarely comes to the jobsite – to compliant – only when required or infrequently – to exemplary – visits are frequent, and managers seek out interactions with employees.

“When it comes to the eight leading indicators, I always go to leadership first,” says Eric Buschard, safety director for Monarch Construction Company in Cincinnati. “Construction workers are not necessarily natural leaders. People are at all different levels of leadership.” Questions about leadership uncover strengths (to reinforce) and weaknesses (gaps to address through coaching, mentoring and training).

“Every organization has blind spots and biases. The assessment tool helps shine a light on these,” says Buschard.

Or as Aaron Boggs, director of safety for Pepper Construction of Ohio says, taking a “deep dive” into safety perceptions within specific organizational levels “allows us to better identify improvement opportunities within those specific levels.”

What survey findings surprised Boggs the most, and the least?

“We have an opportunity to better recognize team members for ‘doing the right thing.’ Although we felt we were recognizing and rewarding safe behaviors, we can do a better job,” he says. Perceptions regarding training were least surprising. “We knew we had opportunities to improve this area prior to the assessment. Training has always been a struggle. Since the assessment we’ve implemented monthly safety training calls, video toolbox talks, trade partner roundtable luncheons and a safety training focus group to champion future training opportunities,” he says.

Climate is what the jobsite environment feels like every day to employees.

Engaging employees

Rebecca Klein, director of risk management for Pac-Pacific Mechanical, based in southern California, uses safety training meetings to conduct the assessments. “It’s very hard to do surveys in construction,” she says. “We can have 40 to 60 active job sites, with three to a hundred guys at any one site. It’s a fast-paced environment and answering surveys can become a ‘check the box, get ‘er done’ exercise. During breaks in safety training meetings, employees can use their cell phones to complete assessments.”

Getting the frontline workers to take time for any safety activity is a challenge in almost every industry. “You can have a gung-ho safety professional, a committed CEO, but still it takes time to figure out the best way to get employees to engage in these assessments,” says Goldenhar. “You need the right messaging. You may not have the trust at first. You might have to build up the trust, especially if surveys like this haven’t been done before. It’s important to reinforce that the assessments are completely anonymous. Names are not entered into the system so responses can never be linked back to the employee.”

Once the employees finish taking the anonymous assessment and the company has their safety climate indicator scores, the next step is to go to the SC-SMIS’s large library of 90 different safety management resources designed to strengthen low-scoring indicators. Doing something about the survey responses, is critical to building participation, says Goldenhar. “It’s really important to close the loop.” That means taking visible action steps to address perceived safety program weaknesses. If nothing ever changes, you lose engagement, says Goldenhar.

A ‘shockingly amazing’ library

“It blows my mind. I can’t believe these resources are free,” says Klein. “Shockingly amazing” is how she describes the large library of downloadable resources including safety management policies, procedures, guidelines and templates covering topics such as management safety roles and responsibilities; site safety inspection procedures; incident root cause analysis; “good catch” near miss reporting; the CPWR Foundations for Safety Leadership course, pre-shift daily huddles; a safety observation checklist; safety recognition program guidelines, and many more. The majority of these resources come from large construction companies and have been formatted as generic Word documents so companies can tailor them to their needs.

Dr. Goldenhar says since the SC-SMIS roll-out in January, more than 300 companies globally have created an account and more than 29,000 resources have been downloaded. She recommends companies conduct an annual assessment to track safety climate improvement and find resources to target additional indicators. In particular, she hopes the smallest of the small companies - those with 10-20 or even fewer employees – begin using the SC-SMIS, since there’s no cost to do so.

Making a difference

“I get so excited thinking how all this is free, the assessment tool and the incredible resources,” says Klein. “Accessing all this can make all the difference in the world, especially for smaller contractors and businesses that don’t have the full-time professionals or the resources. Anyone using it can be proactive, increase their knowledge, and even save lives. Yes, it can be a lifesaver.”