Facility Safety

Video: antorti / Creatas Video via Getty Images

hazards

Understanding your

A Step-by-Step Guide to Combustible Dust Protection

By Rick Kreczmer

E

very year, combustible dust fires and explosions continue to claim lives, injure workers and cause extensive property damage. In 2023 alone, there were 53 explosions, 263 fires, nearly 94 injuries and 62 fatalities linked to combustible dust hazards.

Many manufacturing facilities underestimate the danger. Dust from common materials (including metals, wood, plastics, food products, textiles and more) can become a hidden bomb when accumulated, disturbed and ignited. Even small amounts of fine dust, when suspended in the air inside a confined space, create the potential for a rapid deflagration or explosion. That’s why it’s important to understand your dust and implement systematic controls for combustible dust safety. These seven steps will help you keep people and facilities safe.

Understanding Dust Explosions

OSHA defines combustible dust as “a solid material composed of distinct particles or pieces, regardless of size, shape or chemical composition, which presents a fire or deflagration hazard when suspended in air or some other oxidizing medium over a range of concentrations.”

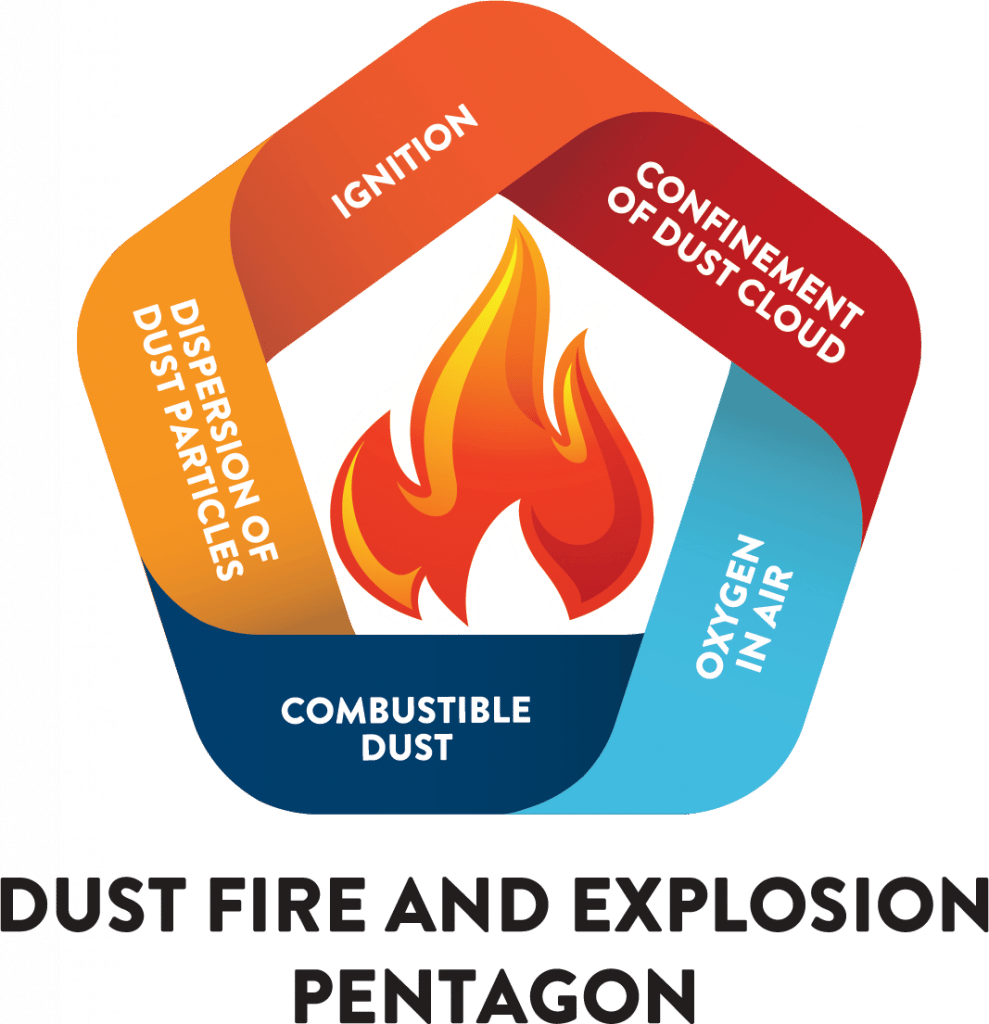

To grasp why even small amounts of dust can trigger devastating events, you need to understand the Dust Explosion Pentagon. There are five interdependent elements that must be present for a dust explosion or deflagration. Each of these is necessary; leave out even one, and the explosion cannot occur.

A Step-by-Step Guide to Combustible Dust Protection

Managing combustible requires a structured approach, beginning with identifying the hazard, analyzing how it behaves in your process, and then engineering the right safeguards. The following steps outline the foundation of an effective combustible dust safety program, including compliant design for the dust collection system.

STEP 1: Identify and Test Your Dust

Many common industrial materials can become combustible when reduced to fine particles. These include organic dusts (food ingredients like flour, sugar, starches, cocoa, wood and textile fibers), metals (aluminum, magnesium, titanium, iron), and synthetic materials (plastics, rubber, and certain chemicals). Combustibility depends not only on material type but also on dust characteristics such as moisture content, particle size, and shape.

Because of this variability, the only way to know for certain if a dust is explosible is to test it. Facilities may sometimes rely on published industry data if their dust closely matches a known material, but testing actual process dust is the most reliable method. A clean, representative sample should be collected and submitted to a certified lab following the lab’s guidelines. Common laboratory tests include:

• Go/No-Go screening test: Determines whether dust is explosible when airborne.

• Explosion severity testing: Measures Kst (rate of pressure rise) and Pmax (maximum explosion pressure), which classify dusts from ST 0 (non-explosive) to ST 3 (very strong explosion).

• Additional tests (as needed): Minimum Ignition Energy (MIE), Minimum Ignition Temperature (MIT), or Minimum Explosible Concentration (MEC)

Graphic credit: RoboVent

STEP 2: Conduct a Dust Hazard Analysis (DHA)

Once you know whether your dust is explosible, the next step is to understand how and where risks arise in your facility. A Dust Hazard Analysis (DHA) is a structured review of processes and equipment to identify situations where a combustible dust explosion could occur. A DHA provides the roadmap for prioritizing safeguards and designing systems that prevent everyday dust from becoming an explosion hazard.

A DHA typically asks:

• Where is dust generated, conveyed or collected, and could it form a cloud?

• What ignition sources are present (sparks, hot surfaces, static discharge)?

• Where does confinement exist (ductwork, hoppers, enclosures)?

• What are the potential consequences if an event occurs?

The DHA will provide clear recommendations for changes to processes or equipment design to reduce the risk of a deflagration. NFPA 660 requires facilities handling combustible dust to complete a DHA and revalidate it every five years.

STEP 3: Install Spark Protection

Uncontrolled sparks and embers are a leading ignition source in dust collection systems. Spark control devices should be installed upstream of the collector to intercept hot particles before they reach confined spaces. Selecting the right technology depends on the dust type, spark characteristics, and process speed. Options include:

• Passive systems such as centrifugal collectors, cyclones, mesh screens and dropout boxes are simple, low-maintenance, effective for slow-cooling embers.

• Active systems use sensors to detect sparks and extinguish them instantly with water or chemical spray. They are best for fast, energetic sparks in high-risk processes.

Graphic credit: RoboVent

STEP 4: Match Fire Suppression to the Hazard

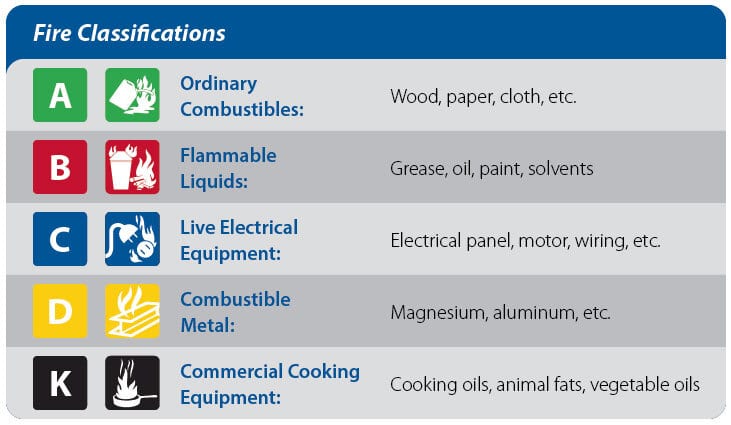

If sparks do reach the collectors, the filter media provides ample fuel for a dust collector fire. Fire suppression systems are needed in the case of a fire inside the collector. The choice depends on dust characteristics and where the collector is located.

• Water sprinklers are economical and effective for most Class A fires; they are not safe for combustible metals (Class D).

• CO₂ systems are residue-free, but are not suitable for occupied areas.

• Dry chemical agents are more expensive and messier, but they are effective across many fire classes, including Class D metal fires.

STEP 5: Equip Collectors with Deflagration Protection

Collectors handling combustible dust must be designed with NFPA-compliant explosion protection. Core elements include:

• Explosion vents relieve rising pressure safely before it builds to explosive levels. Flameless vents should be used for indoor units.

• Isolation devices (inlet valves, rotary airlocks) to prevent pressure and flame from propagating back into the facility.

• Chemical suppression systems are recommended for high-risk applications; they detect and extinguish an incipient explosion inside the collector.

Managing combustible requires a structured approach, beginning with identifying the hazard, analyzing how it behaves in your process, and then engineering the right safeguards.

STEP 6: Place Collectors for Safety

Where the dust collector is located affects both design and protection requirements:

• Outdoor placement is generally recommended when possible. Collectors can vent directly to a clear safety zone, with inlet/discharge isolation devices to prevent flame or pressure from traveling back into the facility. This simplifies explosion protection and minimizes risk to personnel.

• Indoor placement may be necessary in space-constrained facilities, but it requires added engineering controls. Options include ducting vents to safe, unoccupied areas, installing flameless vents that arrest flames while relieving pressure, or using chemical suppression systems where venting is impractical. These solutions increase cost and complexity but may be the only feasible choice.

STEP 7: Maintain Housekeeping and Preventive Maintenance

Even the best systems can’t protect a facility if dust is allowed to build up or safety devices fail. Key practices include:

• Regular cleaning of overheads, floors and machinery to limit dust accumulations.

• Inspection and testing of spark arrestors, suppression systems and isolation valves.

• Documentation of inspections, maintenance and dust levels.

• Revalidation of your DHA at least every five years.

Designing for NFPA Compliance

Effective combustible dust protection is more than just good practice; it’s a compliance requirement. NFPA standards (including 660, 68 and 69) establish clear guidelines for safe dust collection system design.

Because every process, material and facility is different, achieving compliance requires more than off-the-shelf equipment. Working with a qualified dust collection engineering firm ensures your system is properly sized, configured, and equipped with the right spark, fire, and explosion controls.

Rick Kreczmer, President of RoboVent, is an industrial air filtration industry veteran with more than 25 years of experience in sales and executive management. He has led the company through new product innovation and market initiatives to lay the foundation for continued growth and profitability in an evolving manufacturing environment. Download RoboVent’s free Visual Guide to Combustible Dust Collection for detailed instructions and NFPA compliance checklists.