Innovations

in hand protection

Photos courtesy of Magid.

PPE

Let’s compare our options to increase efficiency and comfort

By John Heniff

t’s time to put in your next PPE order. But now you’re faced with a tough decision: You see two gloves that satisfy all the basic safety requirements for your workplace, but one is an innovative product that has additional premium features and the other looks like a more affordable option. It may be tempting to go with the less expensive alternative. But, when compared side-by-side, top-of-the-line PPE has several benefits that give you and your workers more than your money’s worth, and might actually save you money in the long run.

I

Durability leads to cost savings

Many new and innovative PPE choices are much more durable than their simpler counterparts, so they last for use-after-use. You’re essentially paying for quality up front that will last longer (and will ultimately be more cost effective) than an economy model. Think of it like comparing a hammer with a steel handle vs. a wood handle. There’s nothing wrong with using a wood handle for lighter-duty jobs. But if you’re using that hammer on harder materials or know you’ll need it for a long time, you’ll probably invest in a tougher tool. The same goes for PPE. If the task is a little rougher, with more abrasion or wear hazards, you’ll want to consider a higher-end option.

Take glove coatings, for example. Newer coatings released in 2023 stand out in abrasion testing to surpass 30,000 revolutions — far exceeding the baseline of a Level 6 rating. With this added durability, top-of-the-line advancements can help PPE last longer while maintaining its functionality.

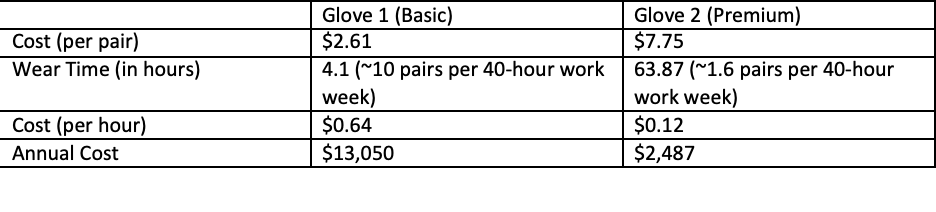

When it comes to considering cost, you can often have it all by getting a higher-end more expensive glove that actually saves you money through lower total cost of ownership. See the table below as an example. Glove 1 is nearly three times cheaper per pair compared to Glove 2. But, when put into use, Glove 2 lasts over 15x longer, giving it a lower cost per hour and making it the smarter investment on an annual basis by over $10,000.

Environmental sustainability

If your workers are going through gloves once a day or even a few times a shift, the number of gloves they throw away adds up by the end of a week, month, and year. If your company is looking for ways to be more environmentally sustainable or just looking to limit the excessive changeover of PPE, top-of-the-line PPE innovations made with the latest technologies give them greater durability and longer service time than economy model alternatives.

Versatility leads to efficiency

Standard work gloves are often designed for one environment or application, which is perfect for workers who perform less varied tasks that don’t require specialized protection. But if your workers operate in multiple environments throughout their day, using only one type of glove won’t make them as efficient if the coating is specific to just one or two environments. Even worse, workers might remove their gloves if they get in the way of finishing the job, putting them at risk of injury.

Recognizing these common pain points, PPE manufacturers got to work on an intelligent glove coating with long-lasting grip in almost any work environment. Designed with special stabilizers that enhance performance, this technology allows workers to precisely assemble small parts, handle rough and heavy materials, pick up oily and slick items, and easily transition back to assembling small parts, all in one shift without the need to change or remove gloves. With these advancements, the right palm coating can make a difference in how your workers efficiently get the job done while working in a variety of conditions.

Comfort leads to compliance

A common reason workers take off their PPE mid-shift is because it can become uncomfortable over the course of the day. Workers say older glove models make their hands hot, sweaty, and itchy, impacting their performance and putting their safety at risk if they take them off to provide relief. One study found that over 70% of hand injuries are the result of workers not wearing gloves at the time of injury. Top-of-the-Line PPE has been designed with worker comfort in mind with the development of new glove shell materials that are over 50% lighter in weight than comparable glove shells of the same cut level. In addition to this lightness, the shell is engineered to be breathable and make your workers’ skin feel cooler while they wear it.

Other cut-resistant glove shells are made with yarn that has no inner core, that’s 30% lighter than similar HPPE, cool to the touch, and doesn’t irritate your worker’s skin. These glove materials are infused with strength-enhancing microparticles instead of utilizing a cut-resistant core like steel or fiberglass that can break down over time and poke through the fabric, scratching the skin and causing contact dermatitis. New impact gloves have an enhanced venting system on the back of the hand for up to 60% more airflow to help dissipate built-up heat. No matter your workers’ PPE needs, new innovations like these can create fewer complaints and fewer headaches for you and your team.

How to analyze your PPE usage

Before you can decide between top-of-the-line PPE and economy PPE, know as much as possible about your current purchasing and use information. Start by gathering the latest statistics and figures on your PPE spend. Look through your invoice history or contact your finance department for style numbers, sizes, the number of quantities ordered, and costs. Look through your notes for how long PPE lasts on average, too. Whether it’s easier to review it by day, shift, or even hour before they’re turned over, this will help you make the most informed decision.

If you’re looking for more input once you’ve calculated your jobsite’s PPE usage, consider consulting with a professional safety expert for a safety assessment analysis. Experts can assess your workers’ PPE usage as well as your current PPE spend to find a suitable item that will fit your budget.

With a little communication and wear-testing, you can find a product that fits your budget, meets your safety specs, feels comfortable for workers to wear, and gives everyone the peace of mind that it will keep them safe on the job.

John Heniff is a safety writer at Magid — proud U.S. manufacturer and distributor of head-to-toe PPE since 1946. For more information about Magid’s safety products and expertise, visit magidglove.com or call 800-444-8030.