Construction

Worker Safety

Photo: Diversified Fall Protection

Reshaping the Future of

Proactive fall protection programs will prevent falls & prevent tragedies

By Philip Jacklin

A

mong causes of injury and fatality in the workplace, falls are one of the most dangerous hazards workers can experience. According to the U.S. Bureau of Labor Statistics (BLS), it is the most common source of job-site injuries and fatalities for construction workers, and the third leading cause for general industry workers. Moreover, the number of workers who die annually from falls has increased in recent years, with approximately 885 deaths in 2023. It seems that if we want to reverse this trend, we must do more than simply provide PPE to mitigate fall injuries. In fact, a 2021 study found that nearly 60 percent of fatal falls occurred while the worker was using fall protection equipment!

Every employer with workers at-height should commit to preventing falls from occurring in the first place. If we can prevent the fall, we can subvert the chance of injury or fatality. This article will encourage organizations to transition their safety programs to a more proactive approach in protecting their workers, as opposed to supplying reactive fall protection equipment that does not remove the hazard from the environment nor prevent the fall from occurring. If no falls occur, no fall injuries occur!

The Most Effective Fall Protection

OSHA currently requires General Industry employers to provide some form of fall protection to any employee exposed to a fall of 4ft or greater (construction companies are mandated at 6ft). However, not all fall protection equipment is created equally. Furthermore, some employers only begrudgingly invest in fall protection and supply just enough equipment to maintain minimum OSHA compliance, without considering what would be the most effective methods in preventing falls.

OSHA compliance does not inherently guarantee worker safety. If a worker still falls and is injured while using an OSHA-compliant solution, it obviously was not effective enough in mitigating the hazard and protecting the worker. User compliance is a key component in determining the effectiveness of a fall protection solution. The best fall protection method is the one that workers will use properly every time.

Graph: Diversified Fall Protection

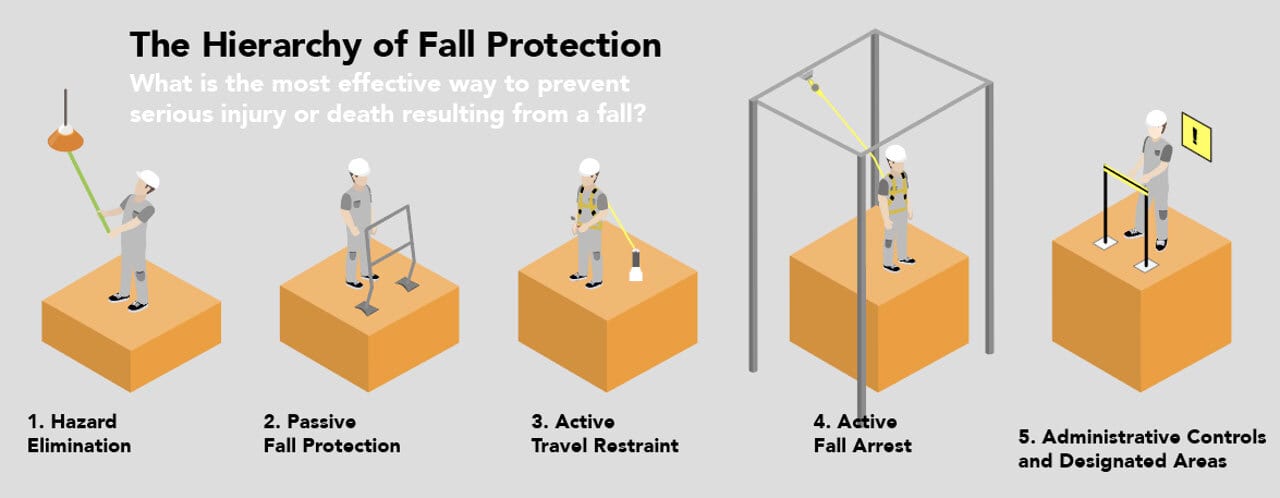

The Hierarchy of Fall Protection Controls

According to the Hierarchy of Fall Protection Controls (see Graphic A), hazard elimination is the most effective form of fall protection because it removes the fall hazard from the work environment. Hazard elimination can be accomplished by several means, but changing how the task is performed or utilizing engineered controls are two common methods.

Many tasks currently being performed at height could be modified to reduce the amount of time workers are exposed to fall hazards. For example, many construction companies now ship pre-cast concrete panels to job sites for final assembly. The workers tasked with installing the panels are only exposed to falls at the end of the process, instead of further exposure while forming tall vertical concrete panels in place.

Engineered controls are when a work area is redesigned to isolate the worker from the fall hazard. For example, HVAC equipment could be relocated to ground levels instead of being installed on rooftops, or machinery could be moved farther from the fall hazard to reduce the exposure to the worker. Architects can provide fall protection during building design by including high parapet walls on rooftop perimeters or any mezzanine areas.

OSHA is vague on retraining requirements to refresh workers’ knowledge on the subject matter, but industry consensus suggests conducting annual fall protection trainings at a minimum.

Fall Prevention vs Fall Arrest

If hazard elimination proves to be infeasible or impossible to adapt to the fall hazard, we can look further down the Hierarchy for the next most effective form of fall protection: fall prevention. Guardrail is the most common form of fall prevention, as it physically hinders the worker’s access to the fall hazard and proves very effective in preventing falls. Even ornamental parapets can be considered fall protection if they are 42” high (among other specifications meeting OSHA guardrail requirements).

When guardrail is deemed infeasible or cannot be safely installed in a specific work area, many organizations assume that providing fall arrest equipment is their only other option. However, fall restraint equipment can be deployed as a last resort to prevent the user from physically reaching their fall hazard. Fall restraint systems utilize a lanyard that is long enough to allow the worker to perform their job, but short enough to prevent them from falling off their walking working surface. Restraint systems can be subject to limitations in certain scenarios, but their effectiveness deserves to be considered before using fall arrest equipment.

Fall arrest equipment is effective at saving lives & limiting the severity of injuries incurred during a fall, but only if the equipment is used properly. Employers must be vigilant in enforcing user compliance because equipment neglect can lead to unmitigated injury. For example, if a worker fails to don their harness properly, they risk further injury caused by increased movement or malfunctioning during fall arrest. Or, an employee does not work above the minimum required fall clearance for their supplied fall arresting device. In both scenarios, the user’s injuries would be exacerbated by their neglect because they failed to properly use their equipment. Fall arrest equipment must be used specifically as instructed by the manufacturer, or else results cannot be guaranteed. It is the employer’s responsibility to ensure workers are trained to use their equipment properly.

In many scenarios, especially in the construction industry, fall arrest may be the only feasible means of providing fall protection to workers. However, it’s important to acknowledge that the likelihood of the fall is not decreased when using fall arrest. The equipment can only limit the severity of injury incurred, as long as the user has followed all manufacturer instructions. While injury will be limited, OSHA and ANSI standards still allow up to 1,800 pounds of force to be felt by the fallen worker, which could still cause minor injuries. Unmitigated falls from heights can be fatal, so minimal injury is seen as better than the potential alternative.

Train Workers to Increase User Compliance

If an organization has people actively using fall protection equipment, they are required to provide initial fall protection training to those workers designated as an Authorized Person. Per OSHA, only an Authorized Person is permitted to use fall protection, and their initial training must teach them how to work safely at heights. OSHA is vague on retraining requirements to refresh workers’ knowledge on the subject matter, but industry consensus suggests conducting annual fall protection trainings at a minimum. Every organization must find out at what frequency retraining must occur to continue effectively protecting workers.

Unfortunately, many companies only begin to prioritize fall protection once a major fall occurs. There is never a bad time to schedule a stand-down training with your entire company to help bring awareness to this hazard and educate workers at every level of the organization on how they can contribute to their communal safety. Hopefully, these preventative trainings can occur before a major incident occurs. Regardless, encouragement & empowerment through education can help employees understand the importance of participating in providing their own personal safety. The aforementioned 2021 study also showed that workers were 8 times more likely to use fall protection simply because they knew it was required by their employer.

Conclusion

During National Safety Month, it’s important to honor the workers who have been injured or have died while on the job. Employers are required, by law, to provide a safe workplace for their employees, and we should all feel a shared responsibility to ensure everyone makes it home safely. One of the best ways to honor fallen workers is to commit to finding solutions that will prevent something similarly tragic from occurring ever again. This act alone will not mend broken bones nor bring back those that passed away, but it can help prevent future accidents from occurring and unnecessary lives from being lost.

Philip Jacklin is Continuing Education Program Manager for Diversified Fall Protection. He is an AIA continuing ed provider, QSSP & OSHA-30 certified, and has been a partner to the fall protection industry since 2018. Philip has a background in customer advocacy, team leadership, and fostering camaraderie among peers. He enjoys playing music, writing, and spending time in the sunshine with his family in Virginia Beach, VA. He can be reached at pjacklin@fallprotect.com.