ADVERTORIAL

Streamline Your Gas Detection

Rendering: Viktoriia Voievodina /

iStock / Getty Images Plus

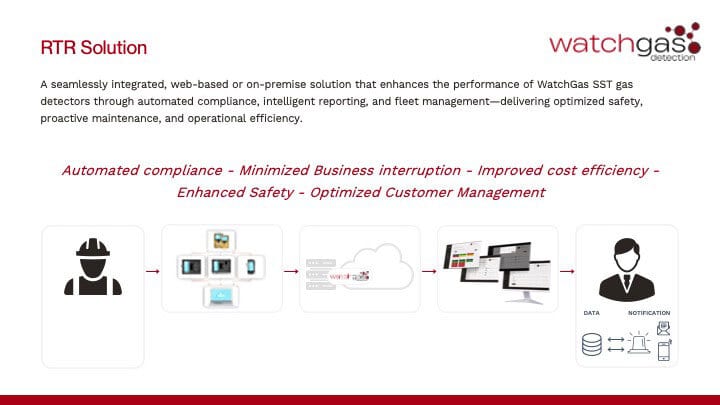

WatchGas detection RTR solution offers automated compliance efficiency and managed cost of ownership

By WatchGas

K

eeping a gas detection fleet tested and in good working order (compliant) can be extremely challenging and time-consuming, taking hundreds to thousands of hours each year for a corporation and prevents industrial safety groups from conducting proactive safety initiatives.

Unexpected gas detector failure, missed test gas replenishment and testing bottlenecks, created by inefficient gas detectors, cost thousands to tens of thousands of dollars each year in worker downtime and unbudgeted high repair costs.

With the WatchGas RTR solution the plant safety level can be increased, and the gas detection fleet cost of ownership can be better managed, reducing costs.

Automated Compliance Efficiency

For safety managers today it is extremely challenging to keep the gas detection fleet compliant, in good working order and being used properly by staff.

Daily bump testing with gas, calibration every 6 months and verifying the workers are using the equipment can be very time-consuming.

Hundreds of hours each year are spent coaching teams to test the equipment and wear it when safety management could be focused on proactive safety initiatives.

For remote workers this understanding of fleet compliance levels, by the safety team, becomes even more challenging as there is no easy way to gather the status of the detector so often a manual record (bump test log) is used, and review only occurs at monthly safety meetings.

Manual recording of these “logbooks” can introduce error and are not easily viewable remotely.

When an audit by corporate safety or OSHA occurs, it is extremely challenging to gather all the information. In extreme cases when an incident occurs there is a laser focus by OSHA and the corporation on the compliance level of that product. During an audit, if OSHA finds that the fleet of gas detectors is not compliant, fines can be up to $16,550 per day.

During daily operations if a worker’s gas detector goes into an alarm, the typical procedure is to evacuate to a muster point and then check in with safety and file an incident report. Often gas alarms go unreported. This means leaks that are periodic can grow larger and cause major issues. With the WatchGas detection RTR solution, the challenge of compliance management is simplified via automation.

For plant level workers having inexpensive kiosks throughout the facility as well as docking stations allows the workers to have multiple points of access to test and gather all the information frequently.

For remote individual workers using simplified testing on the WatchGas detector and uploading via the WatchGas SST App on smart devices, the compliance information is quickly and frequently uploaded into the RTR solution with just the tap of a device.

For day-to-day management, the worker will get updates on their gas detector on a frequent basis to test the equipment.

If the worker chooses not to test the detector, a flashing indicator on the device will inform personnel and safety management around them, from a distance, so they can coach the worker that their detector requires attention.

If the detector is still not tested an automated email will be sent out to operations management so coaching the worker on proper procedure can occur.

If the detectors are not being uploaded as “checked into the system,” this will also mean an automated email to management highlighting that the detectors need to be checked in.

Gas alarms are immediately transmitted to leadership through RTR software when a product is uploaded into the system guaranteeing all alarms are seen and proactive measures can be taken to eliminate future concern.

Detector Datalogger information is easily reviewed through the RTR software allowing the team to quickly understand the type of gas and what concentrations were released. Calibration certificates are also readily available to verify the accuracy of the test.

With all these automated checks in the system a compliant gas detection fleet can be assured with minimal costs to management and minimal touch points by the safety group so they can focus on proactive safety initiatives.

The RTR solution software is highly visual showing just the specific information that management needs to confirm compliance and quickly make decisions. Emails are sent with the most critical information highlighted so immediate action can be taken.

Managed cost of ownership

The operations of the gas detection fleet can also be an extreme challenge with many unexpected costs and inefficiencies.

Downtime associated with unexpected gas detector failure, missed test gas replenishment and worker testing bottlenecks, created by inefficient gas detectors, can drive unnecessary costs to be in the tens of thousands of dollars each year. Budgeting for gas detector maintenance can be extremely challenging as its unknown month to month what the cost will look like.

With the RTR solution the health of the gas detection fleet is constantly monitored, and the management costs can be adjusted to meet the needs of the business.

Gas detection sensor health, detector and docking station battery levels, test gas bottle levels and product lifetime are proactively measured and monitored so maintenance teams can predictably order replacement parts and schedule when maintenance occurs. Parts can be ordered preemptively, reducing the high costs when items are ordered at the last moment. This also reduces the failure rate of gas detectors in the field as they are serviced when required.

Is the company’s focus on changing out the components when they get close to failure and keeping maintenance costs low the most important or is it more important to replace components more frequently to reduce worker downtime? The level can be adjusted to meet the needs of the business.

Often a test gas bottle will run out of gas, and it causes an excessive cost of business interruption and the cost to quickly replace “hot shot service” is extremely expensive.

Managing gas detection fleets typically means ordering an additional 10-20% extra gas detectors so when these critical products suddenly fail, the team can quickly pull from this excess inventory. This results in spending thousands of extra dollars annually on additional inventory purchases and the ongoing maintenance costs associated with it.

As the detector maintenance is better managed with the RTR solution these costs can be minimized by saving thousands each year in reduced business interruption and reduced purchase of such high excess inventory.

With WatchGas gas detectors and docking stations working optimally together gas tests can be performed up to 66% faster than other manufacturers’ equipment, saving tens of thousands of dollars each year in test gas costs and making work teams more efficient by reducing testing bottlenecks.

In synopsis

When a fleet of gas detection products is managed properly and is in good working order the safety level of the plant is increased.

With a solution that simplifies testing and data gathering, even in remote locations, combined with automation that proactively manages the health of the fleet as well as the compliance level and informs management when attention is required increases the efficiency of the operation.

This solution reduces costs by tens of thousands of dollars each year and allows safety, operations and maintenance to conduct their processes more economically and they can focus on other items that drive the business forward.