Industrial hygiene

Put your filter to the test

How to understand MERV ratings and industrial dust collector filtration

By Randi Huckaby

ndustrial dust collectors are proven engineering control systems to maintain indoor air quality and protect the health and safety of your workers. One of the key factors to keeping your dust collector operating efficiently over its lifetime is selecting the right dust collector filters. Many replacement dust collector filters offer MERV (Minimum Efficiency Reporting Value) ratings to quantify filter efficiency. MERV ratings are very useful in the HVAC industry, with higher ratings generally indicating superior filtration. However, MERV ratings don’t reflect how well a filter will perform in the active environment of an industrial dust collection system.

I

More about MERV

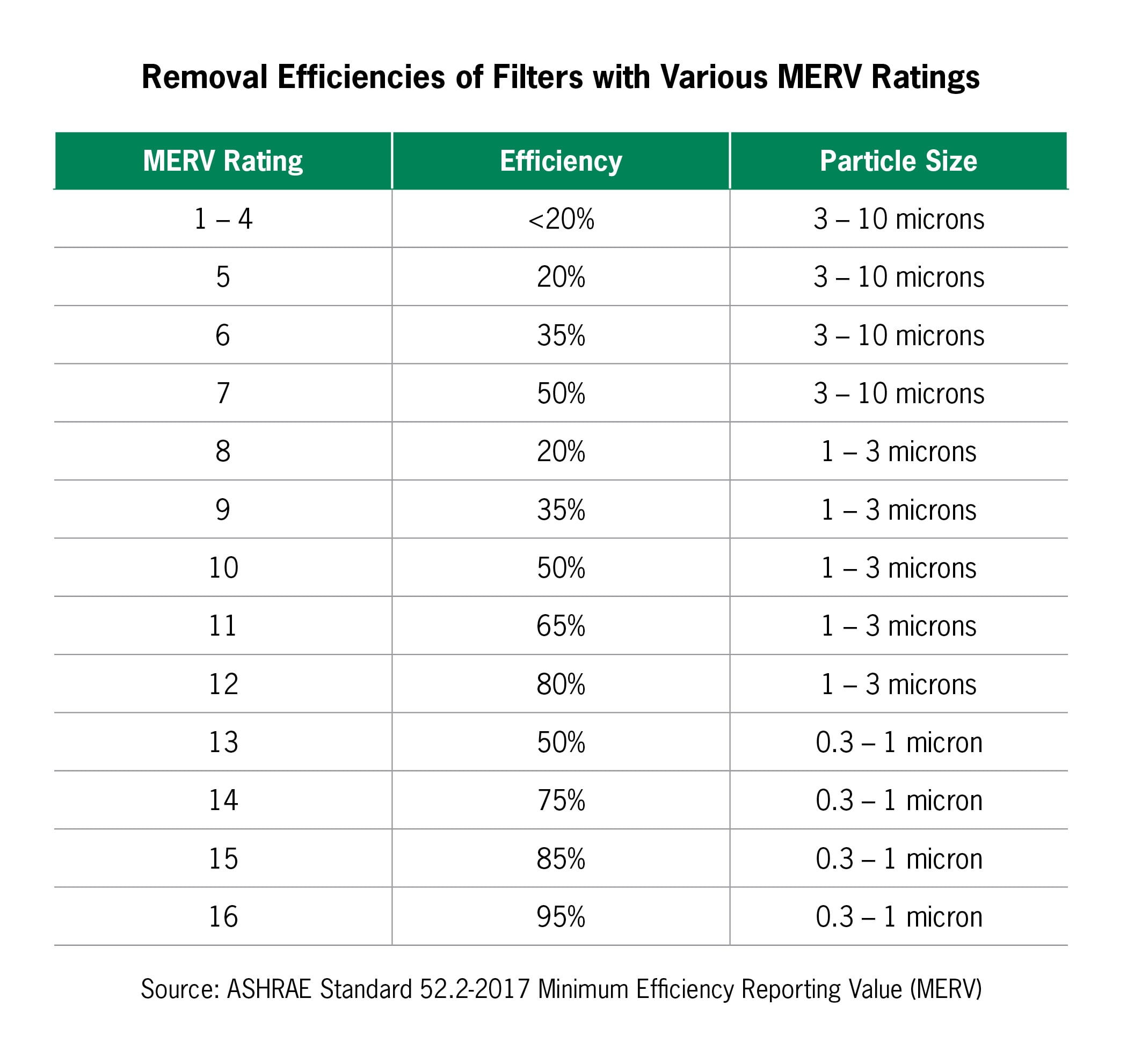

MERV is a measurement scale designed in the late 1980s by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) to compare the effectiveness of air filters. ASHRAE 52.2 defines a test method and rating system in which a filter’s initial efficiency is assigned a number. This number identifies the filter’s minimum performance in removing particulates from an airstream.

The MERV scale goes from 1 to 16 and corresponds to a filter’s ability to capture particles in different size ranges from 0.3 to 10 microns. Higher MERV ratings correspond to a greater percentage of particles captured on each run. MERV ratings are limited with regard to industrial dust collectors because they apply only to new filters and their initial efficiency in a static environment with light dust loading. However, dust collectors and their filter cartridges manage airborne particle emissions over time in a dynamic system.

Industrial dust collection systems face high dust loading, so they are equipped with a pulse cleaning system. The filters are constantly being loaded and unloaded, leading to fluctuations in efficiency and pressure drop. The MERV testing procedure measures initial pressure drop, but not how pressure drop will change over time or how it will affect overall energy usage. These factors have a dramatic effect on the performance of the filter over time, and the MERV rating does not take this into account.

Factors affecting dust collector filter efficiency

As a dust collector runs, dust loads onto the filters and forms a dust cake. This dust cake resists airflow across the filter media. The resistance is measured in water gauge or pascals and is referred to as pressure drop. It is usually between 1 and 5 inches of water. As dust loads and pressure increases, the filter efficiency increases, but the dust collector must work harder. This triggers the pulse cleaning system, which knocks off the dust cake and starts the process over. As a result, the dust cake is constantly changing and so are the pressure drop and filter efficiency. Eventually, the dust load will increase to a level where pulse cleaning is no longer helpful, and the only option is to change out the filter for a new one.

Both higher efficiency filters and dust buildup restrict airflow. With this higher restriction, more energy and compressed air are required to maintain the proper airflow and pressure drop, and this can be costly. MERV ratings don’t take this into consideration.

Photo and chart courtesy of Camfil APC.

ASHRAE Standard 199 testing

The best filter for a dust collector is one that offers the best efficiency and cleaning performance. Dust collector performance is based more on its airflow management, its cleaning system and the media’s ability to load and release dust particles. This can only be evaluated by testing how the filter and the dust collector work together as a system.

In order to determine the efficiency of the dust collection system, ASHRAE created Standard 199, “Method of Testing the Performance of Industrial Pulse Cleaned Dust Collectors,” which is designed to account for the fluctuating dust collector environment in a way that MERV does not. The Standard 199 test method calculates the performance of all industrial pulse-cleaned dust collectors including filtration performance and energy consumption. The resulting summary offers an indication of filter life.

Testing under Standard 199 is conducted in six stages that replicate a real-life dust collector application. The test measures performance parameters including emissions, pressure drop and compressed air usage.

The 199 test is a better method for determining both system and filter performance because it provides an accurate portrayal of the dynamics of the industrial dust collection system as a whole, versus the single filter initial efficiency methodology used in MERV.

Summing it up

Although the MERV scale is a useful tool, don’t rely on it alone to select dust collector filters. MERV ratings apply only to new filters, and the efficiency of dust collector filters changes significantly during actual use. Using ASHRAE Standard 199 gives a more accurate reflection of a dust collection system’s lifetime performance, including filtration.

Randi Huckaby is Product Manager — Dry Filtration APC Global at Camfil Air Pollution Control (APC). Camfil APC, a unit of the Sweden-based air filtration company Camfil, is an industry-leading global manufacturer of dust, fume and mist collection equipment for challenging industrial applications, with production facilities around the world including the Americas, Europe and Southeast Asia. For information, contact 800-479-6801 or 870-933-8048; email filterman@camfil.com; or visit www.camfilapc.com.